Pultruded Fiberglass Door And Frame Components, “100% Made In The U.S.A.”

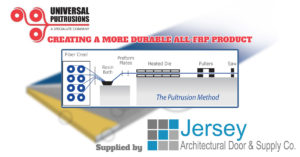

Universal Pultrusions LLC (UniPul) is a Michigan-headquartered manufacturer of pultruded fiberglass door and frame components for use in industrial applications. They produce doors rugged enough to match hollow metal door standards, and are the only company in the world that pultrudes a “monolithic” fiberglass door panel.

Universal Pultrusions LLC (UniPul) is a Michigan-headquartered manufacturer of pultruded fiberglass door and frame components for use in industrial applications. They produce doors rugged enough to match hollow metal door standards, and are the only company in the world that pultrudes a “monolithic” fiberglass door panel.

Universal Pultrusions has been in production since 1986. Ownership changed in 2004 when brothers Keith and Kevin Jensen purchased the business. Acting as the President and Technical Director, Keith used his background in engineering to help refine their development of proprietary fiberglass door technologies.

The company does not outsource any door components, choosing instead to pultrude their own sub-assemblies. Keeping production in-house allows them to follow rigorous quality control standards, and guarantee clients that their products represent a truly “100% made-in-the-U.S.A.” door system.

Special-Lite, Inc. acquired Universal Pultrusions in 2012. The acquisition of such an innovative pultrusion technology was, as the company stated, “important in maintaining and securing a leadership position for Special-Lite in the fiberglass and non-corrosive building entry solution market.” By 2014, Special-Lite had invested in over 65,000 square feet of plant space in an effort to modernize its Marshall, Arkansas plant.

The Many Benefits Of Pultruded Fiberglass Doors

Universal Pultrusions makes the world’s only pultruded, heavy-duty completely sealed industrial FRP door. Every door is 1-3/4” thick and hermetically sealed and moisture and corrosion-proof. Built dimensionally and aesthetically identical to hollow metal doors, FRP doors provide even greater benefits than their conventional equivalents, including:

- 6-pound/cubic foot closed-cell polyurethane core wrapped in 4 layers of reinforced glass fiber and resin, encapsulated to 1/8” at all faces for industry-leading impact resistance.

- Doors Made With FDA and USDA-Compliant Resin

- Stile edges measure 9/16” thick, allowing for optimal screw holding ability.

- Top rail is 6” deep with 1/4” wall thickness, providing reinforcement for closer attachments.

- Field trimming of door possible with standard mortise bottom rail. Optional flush bottom rail improves ease of cleaning and sterilization.

- Standard door widths are 32”, 42” and 48”, with custom widths available up to 5′. Heights can be up to 22′ tall.

- Doors are compatible with standard industry hardware.

- Doors available with thresholds, wall anchors, mullions, center posts,vision lites,frames, and louvers.

Fire-Resistant Doors With Fire Ratings From 20 To 90 Minutes

Universal Pultrusions has unveiled its new FR Series fiberglass doors and pultruded fiberglass frames. These innovative fireproofing products have been tested in accordance with UBC-7-2, NFPA 252 and UL 10C requirements. The FR Series passed the 1-1/2 hour positive pressure test, hose stream test, and 250 degree temperature rise tests. Universal Pultrusions has such faith in the durability of its fire doors that they come with a 10-year parts and labor warranty.

- FR-20: 20-minute fire rating

- FR-45: 45-minute fire rating

- FR-60: 60-minute fire rating

- FR-90: 90-minute fire rating

Want To Know More About Universal Pultrusions’ Fiberglass Doors?

Give Jersey Architectural A Call Now At

(609) 345-0174